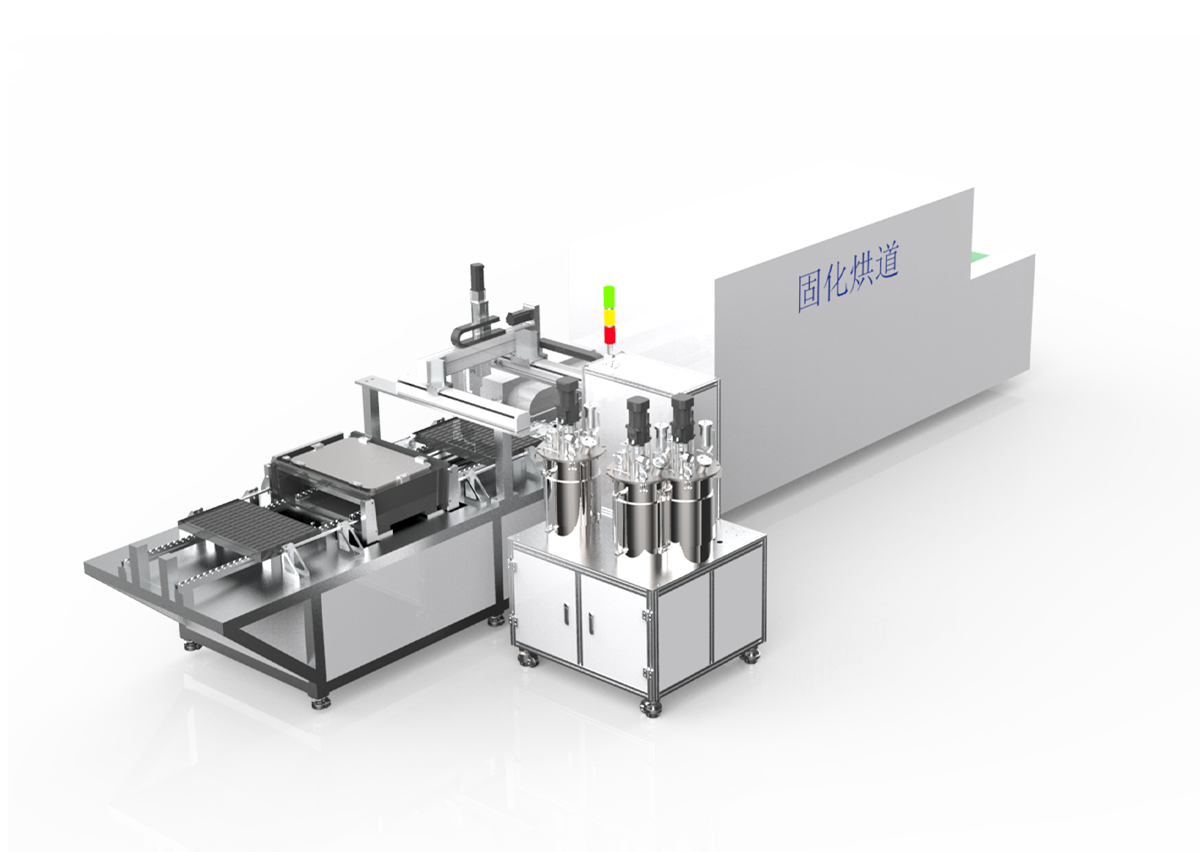

What are the characteristics of the sealing vacuum defoaming and solidification assembly line

source:www.gerwilo.cn | Release time:2025年04月15日1. High degree of automation: This assembly line can achieve automated operation of a series of processes from sealing, vacuum defoaming to solidification. It can correctly control the parameters and running time of each link through preset programs and control systems, reduce manual intervention, and improve production efficiency and product quality stability.

2. Good vacuum defoaming effect: During the sealing process, it can effectively remove bubbles from the material. By placing the sealed product in a vacuum environment and utilizing pressure differences to quickly release bubbles, defects caused by bubbles in the product are avoided, improving the sealing and reliability of the product.

3. High curing efficiency: Equipped with specialized curing equipment and processes, suitable curing conditions such as temperature, humidity, and curing time can be provided according to different sealing materials and product requirements. A fast and efficient curing process helps to shorten the production cycle and improve production efficiency.

4. Strong production continuity: The various processes are closely connected, and the products flow continuously on the assembly line, achieving uninterrupted production. This continuous production method not only improves production efficiency, but also reduces the waiting time of products between processes and lowers the risk of external pollution.

5. High precision control: It has high-precision control ability for key parameters such as sealing amount, vacuum degree, curing temperature, etc. These parameters can be adjusted correctly according to the different requirements of the product, ensuring that each product can meet consistent quality standards and improve the yield rate of the product.

6. Strong compatibility: able to adapt to various types of sealing materials and product specifications. Whether it is the encapsulation of small electronic components or the packaging of large industrial products, production needs can be met by adjusting the parameters and equipment configuration of the assembly line.

7. Environmental protection and energy conservation: By adopting excellent technology and equipment, the discharge of waste gas, wastewater, and waste residue can be effectively reduced during the production process, thereby reducing environmental pollution. At the same time, by optimizing energy utilization efficiency, energy conservation and consumption reduction can be achieved, and production costs can be reduced.

8. Data recording and tracing: With data recording and monitoring functions, it can record various parameters and data in real-time during the production process, such as sealing volume, vacuum degree, curing time, and temperature. These data can be used for product quality traceability and analysis, facilitating enterprises to optimize and improve their production processes, enhance their management level, and improve the traceability of product quality.

prev:

What is the purpose of the Purification Filter Gl…

next:

What is the purpose of the multi station all in o…

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone